- On sale!

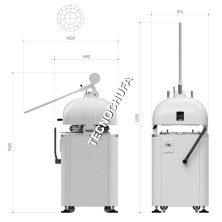

M-BD MANUAL BALLING DIVIDER

TECHNICAL CHARACTERISTICS:

M-BD11

- Divisions: 11

- Circle shape

- Minimum weight: 180 gr

- Maximum weight: 500 gr

- Basin capacity: 5.5 kg

- Head diameter: 400mm

- Capacity per hour: 1300

- Mechanical operating machine. The pressing, cutting and final rounding phases are carried out with levers, while the regulation of the forming chamber is carried out

with a control lever that includes a numerical scale. The machine is delivered with a total of 3 plates.

- The manual rounder dividers are machines that allow you to cut a piece of raw dough into smaller pieces and successively, thanks to an oscillating plate, round each of the

pieces until you get balls of the same shape and weight in a few seconds!

Work cycle

1. manually insert the plate;

2. regulate the opening of the chamber;

3. with the levers press and cut;

4. operate the rounding lever;

5. remove the plate with the balls formed.

USED MATERIALS

- Painted electrowelded steel frame;

- Painted steel or stainless steel cladding.

- Tanks and heads of aluminum anticorodal MG5 with anodizing;

- 304 stainless steel knives and racks;

- Inner surface of the lid and pressure devices made of food polyethylene PE500;

PETG food polyethylene dishes;

- Aluminum ring with chemical nickel plating.

ELECTRICAL POWER SUPPLY

- All machines are supplied as standard with a 400 volt 50 Hz 3 phase connection. Upon request, they can be supplied with different voltages.

- All machines are CE compliant and manufactured in Italy.

MODELS AND SPECIFICATIONS:

M-BD15

- Divisions: 15

- Circle shape

- Minimum weight: 150 gr

- Maximum weight: 360 gr

- Basin capacity: 5.5 kg

- Head diameter: 400mm

- Capacity per hour: 1800

M-BD18

- Divisions: 18

- Circle shape

- Minimum weight: 120 gr

- Maximum weight: 280 gr

- Basin capacity: 5 kg

- Head diameter: 400mm

- Capacity per hour: 2100

M-BD22

- Divisions: 22

- Circle shape

- Minimum weight: 60 gr

- Maximum weight: 220 gr

- Basin capacity: 5 kg

- Head diameter: 400mm

- Capacity per hour: 2600

M-BD30

- Divisions: 30

- Circle shape

- Minimum weight: 40 gr

- Maximum weight: 135 gr

- Basin capacity: 4 kg

- Head diameter: 400mm

- Capacity per hour: 3600

M-BD36

- Divisions: 36

- Circle shape

- Minimum weight: 34 gr

- Maximum weight: 110 gr

- Basin capacity: 4 kg

- Head diameter: 400mm

- Capacity per hour: 4300

M-BD30S

- Divisions: 30s

- Circle shape

- Minimum weight: 25 gr

- Maximum weight: 90 gr

- Basin capacity: 2.7 kg

- Head diameter: 400mm

- Capacity per hour: 3600

M-BD52

- Divisions: 52

- Circle shape

- Minimum weight: 12 gr

- Maximum weight: 40 gr

- Basin capacity: 2.7 kg

- Head diameter: 400mm

- Hourly Capacity: 6200